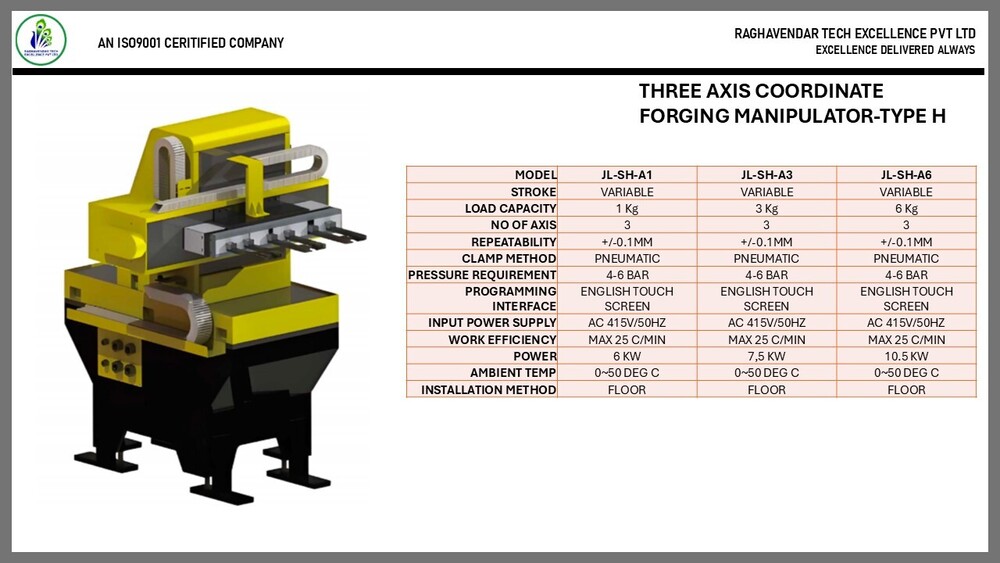

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE H

Price 950000 INR/ Number

About THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE H

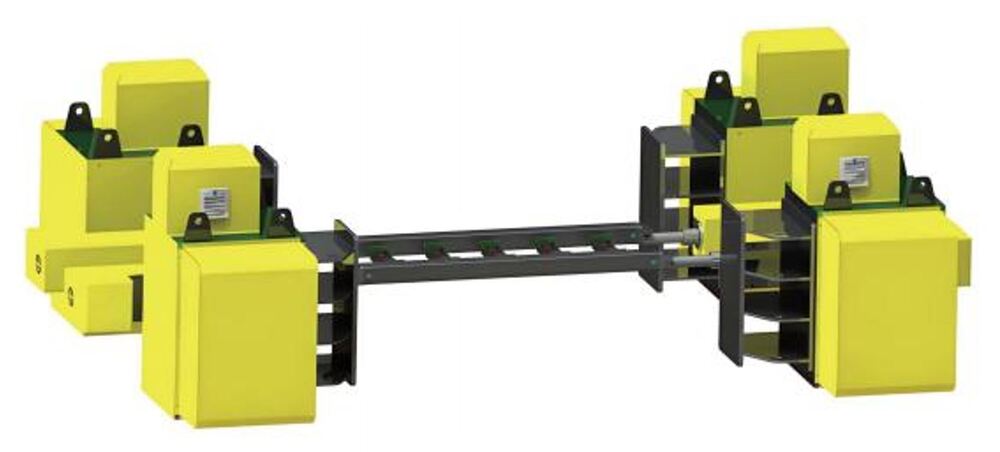

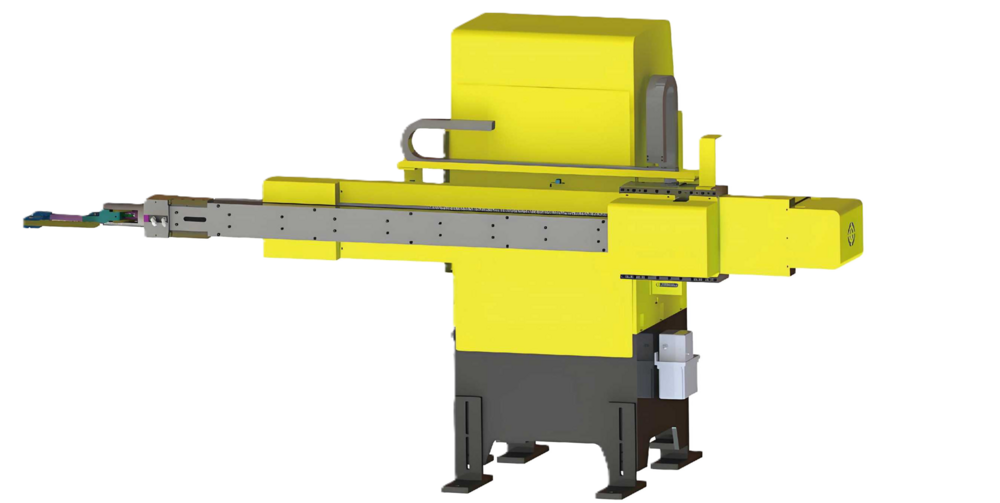

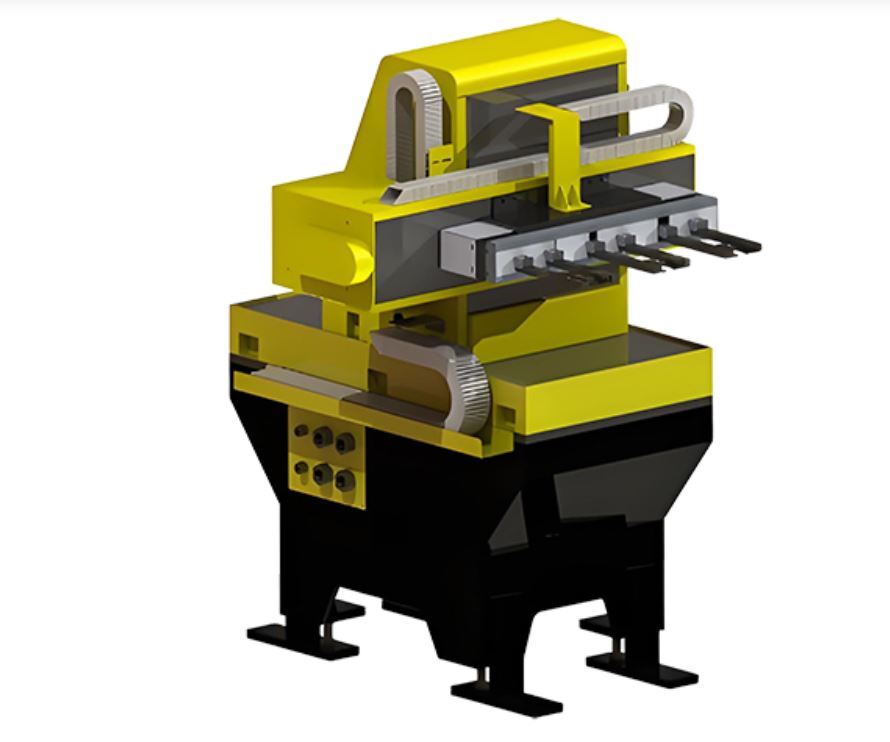

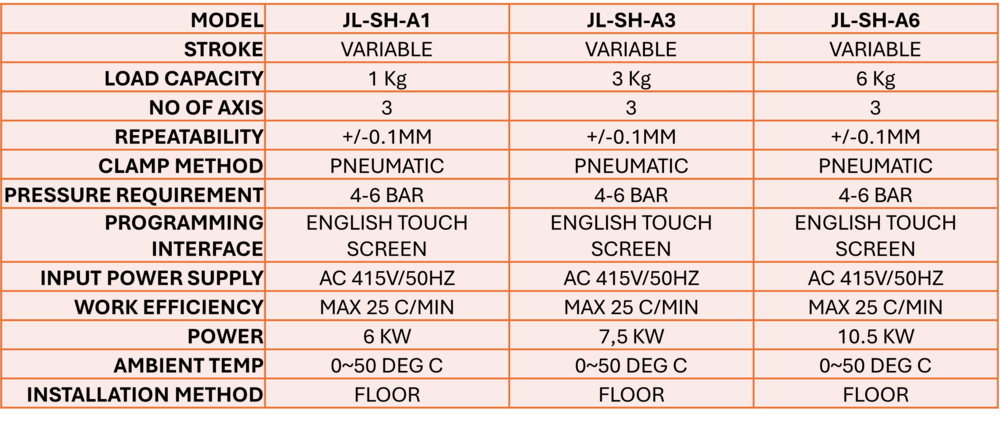

Three-Axis Forging Manipulator (Type H) is a compact and efficient automation solution designed to improve speed, precision, and safety in forging applications. This system is available in three models (JL-SH-A1, JL-SH-A3, and JL-SH-A6) supporting load capacities of 1 kg, 3 kg, and 6 kg per workpiece respectively.

Built with a three-axis coordinated motion structure, the manipulator ensures smooth and consistent movement during pick-and-place or feeding operations. With a repeat accuracy of +/- 0.1 mm, it offers exceptionally stable performance, making it suitable for high-precision production environments.

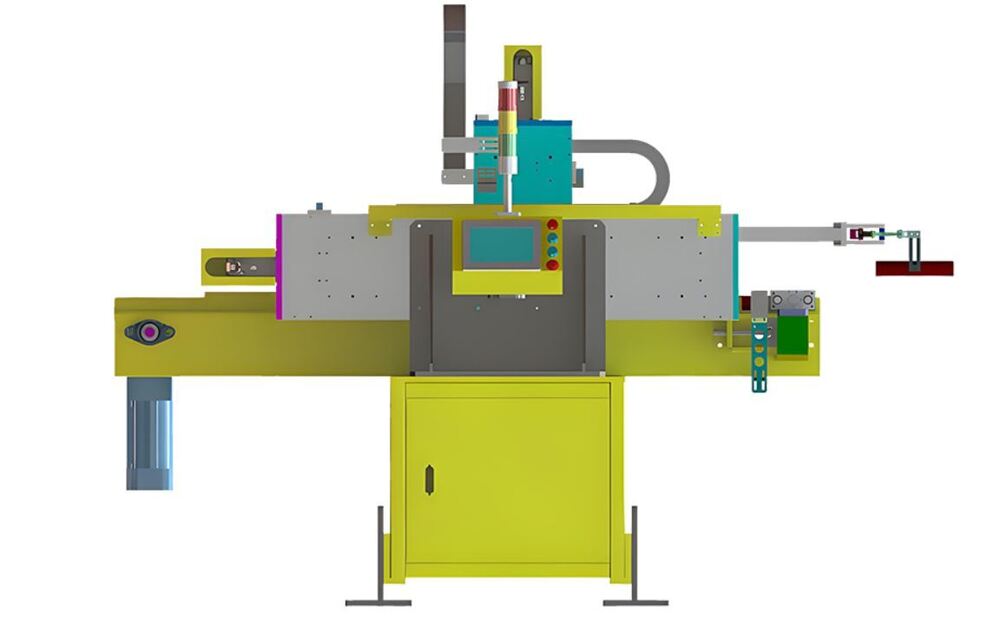

The machine uses a pneumatic clamping mechanism, providing a fast and secure grip on forged parts. It operates on 4.0-6.0 kg/cm2 air pressure and standard AC 220V, 50/60Hz power supply, ensuring easy installation in most forging workshops.

Depending on the model, the manipulator achieves a work efficiency of up to 25 cycles per minute, significantly increasing productivity while reducing operator fatigue. Power consumption ranges from 6 kW to 10.5 kW, offering a good balance of performance and energy usage.

Designed for a working environment of 0C to 50C, the unit supports stable floor mounting for long-term industrial operation. Overall, it is an excellent choice for manufacturers looking to automate handling of small and medium forged components in a reliable, precise, and cost-effective manner.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FORGING MANIPULATOR Category

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A

Price 1500000 INR / Number

Minimum Order Quantity : 1 Number

TWO AXIS COORDINATE FORGING MANIPULATOR

Price 1600000 INR / Number

Minimum Order Quantity : 1 Number

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry