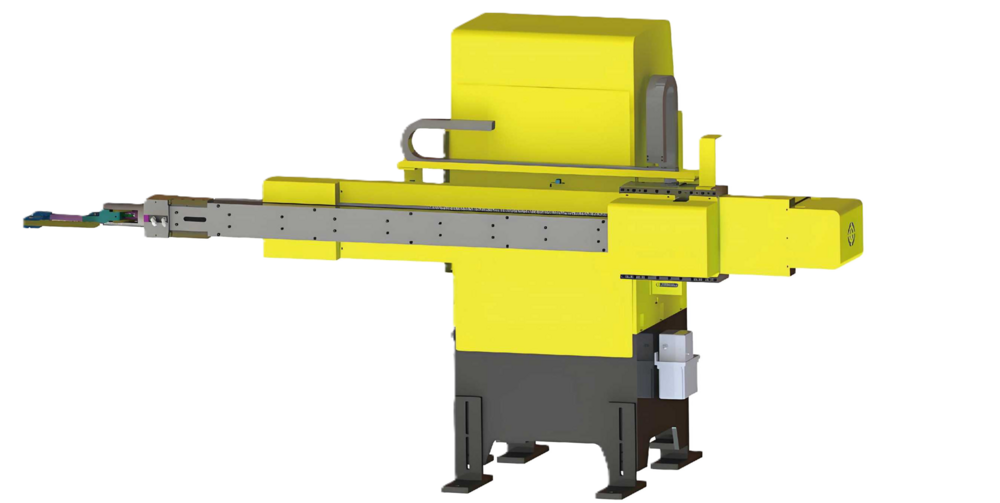

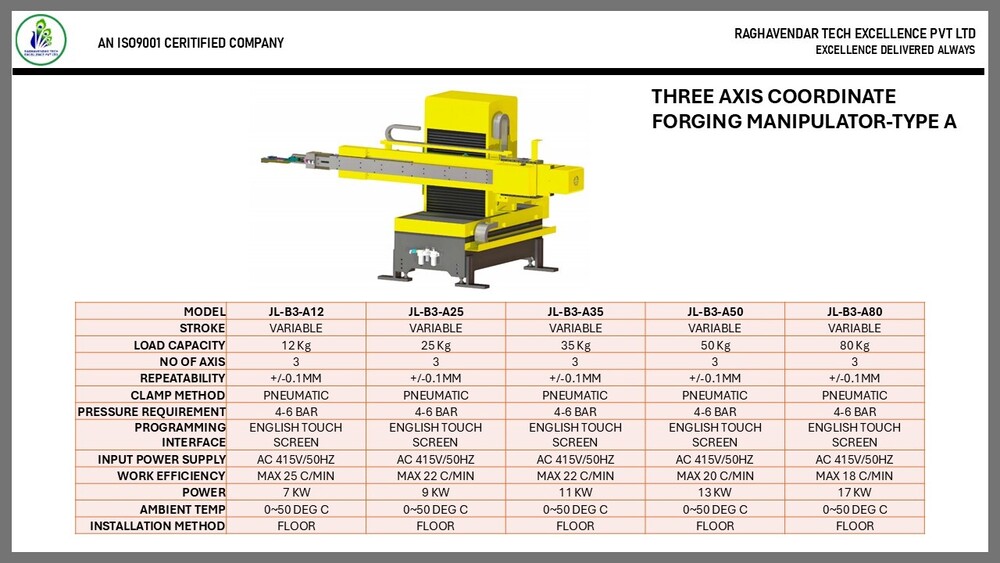

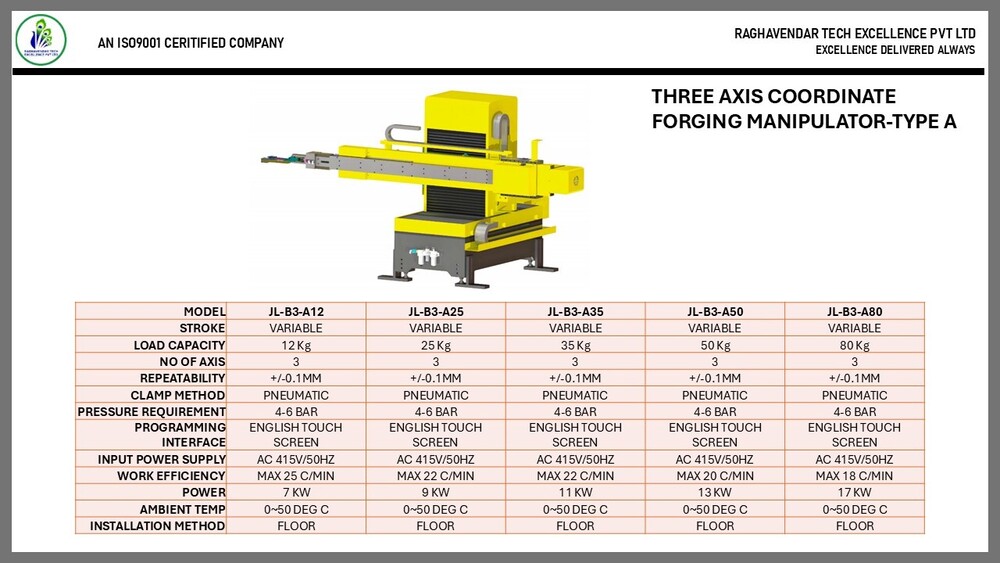

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A

Price 1500000 INR/ Number

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 10 Per Month

- Delivery Time

- 45 Days

About THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A

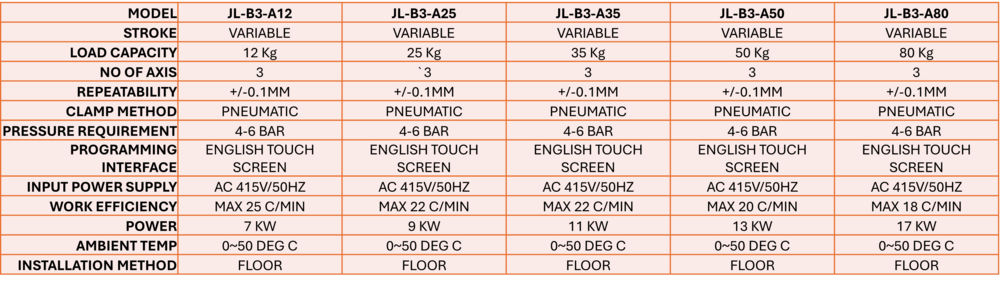

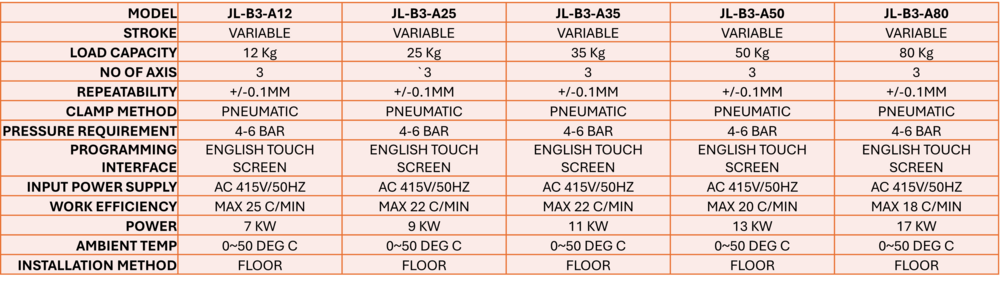

Technical Specifications

-

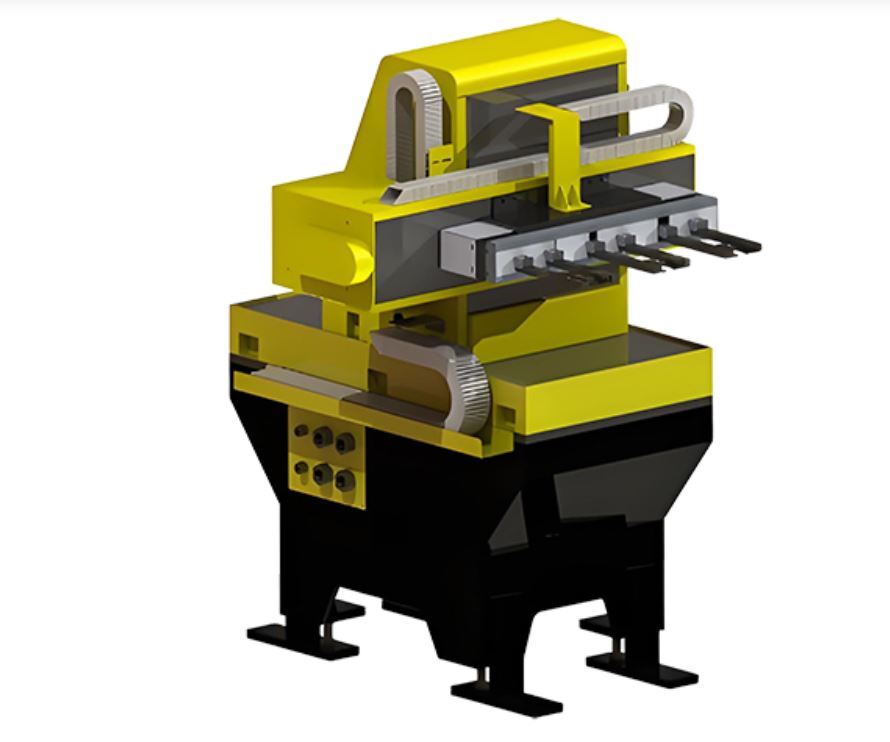

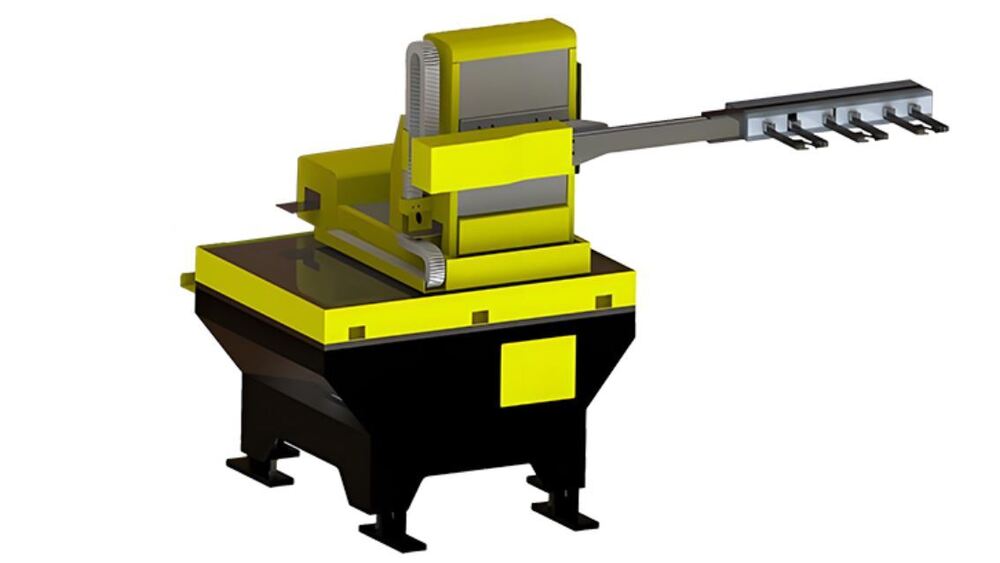

Axes: 3-axis configuration for coordinated motion, enabling complex part manipulation.

-

Load Capacity: Available in multiple models-12 kg , 25 kg , 35 kg , 50 kg , and 80 kg.

-

Repeat Accuracy: +/- 0.1 mm, ensuring high precision and consistent performance.

-

Clamp Method: Pneumatic clamping mechanism for secure and fast grip.

-

Air Pressure Requirement: Operates at 4.0 - 6.0 kg/cm2.

-

Programming Interface: Touchscreen interface in Chinese and English for ease of use.

-

Power Supply: AC 220 V, 50/60 Hz.

-

Work Efficiency: Depending on model, up to 25 cycles per minute for lighter loads; lower for heavier models.

-

Power Consumption: Ranges from 7 kW (for 12 kg model) up to 17 kW (for 80 kg model).

-

Operating Temperature: 0 C to 50 C for reliable performance in industrial environments.

-

Installation: Floor-mounted installation for stability and easy integration in forging lines.

Benefits & Applications

-

Increased Productivity: With fast and precise movement, the V732 can significantly boost throughput on forging floors.

-

Improved Safety: Reduces manual handling in high-temperature zones, lowering risk to operators.

-

Flexibility: Multiple load variants make it adaptable for different forging parts - from small components to heavier billets.

-

User-Friendly Control: The touchscreen interface makes programming and operation simple, even for less experienced operators.

-

Energy Efficiency: Pneumatic clamping and optimized power usage reduce operational costs over time.

Ideal For

-

Automotive forging plants

-

Heavy equipment component manufacturing

-

High-volume production of forged parts

-

Workshops aiming to upgrade manual forging to semi-automated or fully automated lines

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FORGING MANIPULATOR Category

TWO AXIS COORDINATE FORGING MANIPULATOR

Price 1600000 INR / Number

Minimum Order Quantity : 1 Number

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE H

Price 950000 INR / Number

Minimum Order Quantity : 1 Number

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE S

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry