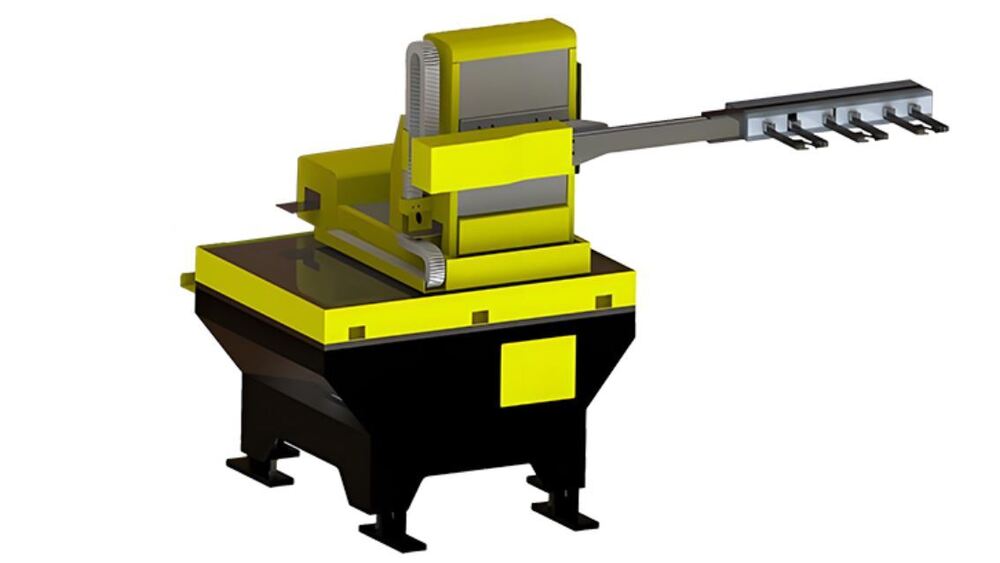

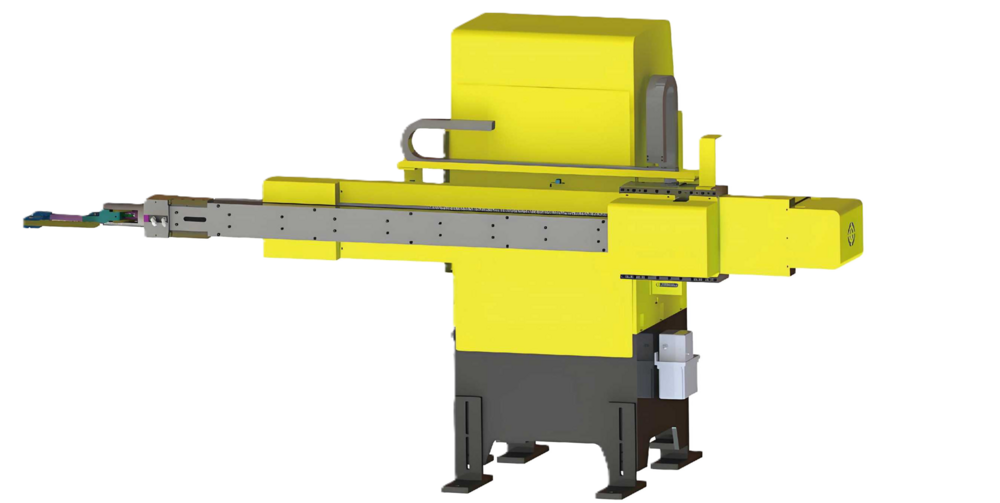

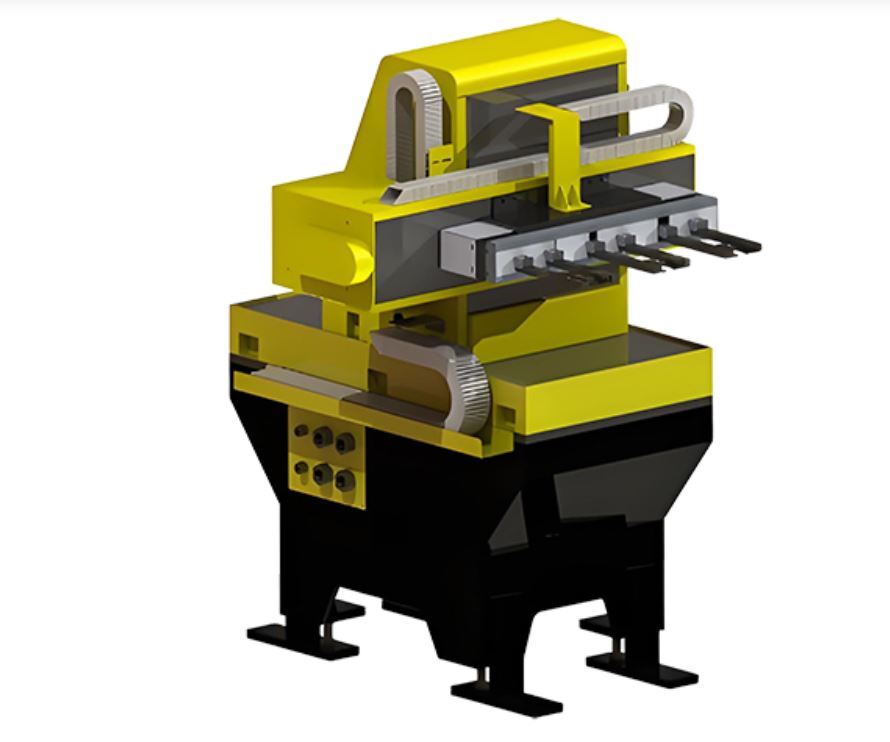

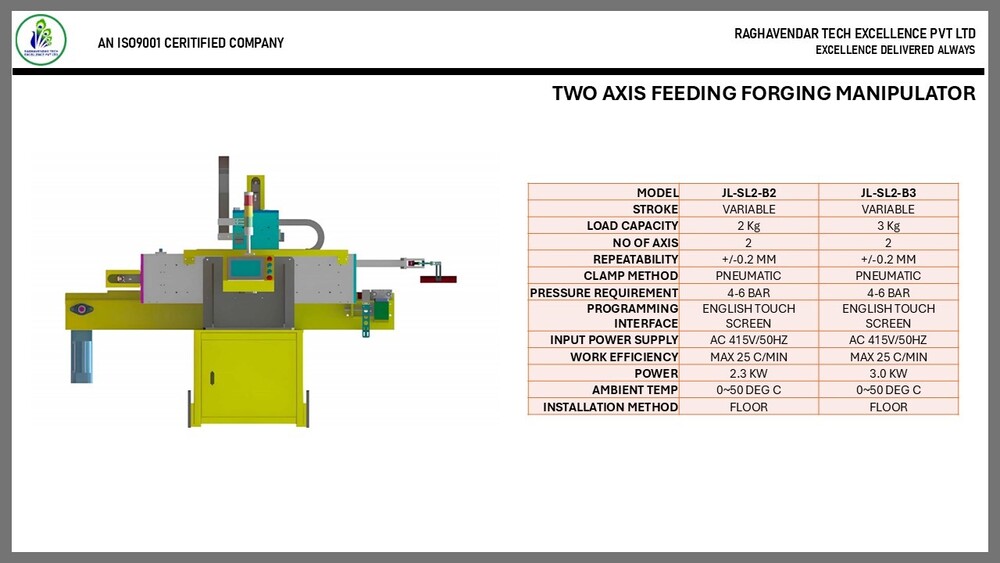

TWO AXIS FEEDING FORGING MANIPULATOR

Price 1000000 INR/ Piece

About TWO AXIS FEEDING FORGING MANIPULATOR

The Two-Axis Feeding Forging Manipulator is a high-precision automation solution built for feeding parts into forging lines. With two axes of coordinated motion and a pneumatic clamping mechanism, it ensures reliable and repeatable handling of smaller workpieces.

Key Technical Specifications:

-

Model Variants:

-

JL-SL 2-B2: for parts up to <2 kg

-

JL-SL 2-B3: for parts up to <3 kg

-

-

Number of Axes: 2

-

Repeat Accuracy:+/- 0.2 mm

-

Clamping Method: Pneumatic

-

Air Pressure Requirement: 4.0-6.0 kg/cm2

-

Programming Interface: Touchscreen (Chinese / English)

-

Power Supply: AC 220 V, 50/60 Hz

-

Work Efficiency: Maximum 25 cycles per minute

-

Power Consumption:

-

B2 model: 2.3 kW

-

B3 model: 3.0 kW

-

-

Ambient Operating Temperature: 0 C to 50 C

-

Installation Method: Floor-mounted

Benefits & Applications:

-

Optimized for feeding forged parts into presses or production lines.

-

High repeat accuracy ensures precise placement and reduces handling error.

-

Pneumatic clamping enables fast and secure grip and release, improving cycle times.

-

Two load variants make it suitable for light-to-medium weight components.

-

Compact and efficient design helps streamline production and reduce labor.

-

Suitable for forging operations focused on automation, safety, and consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FORGING MANIPULATOR Category

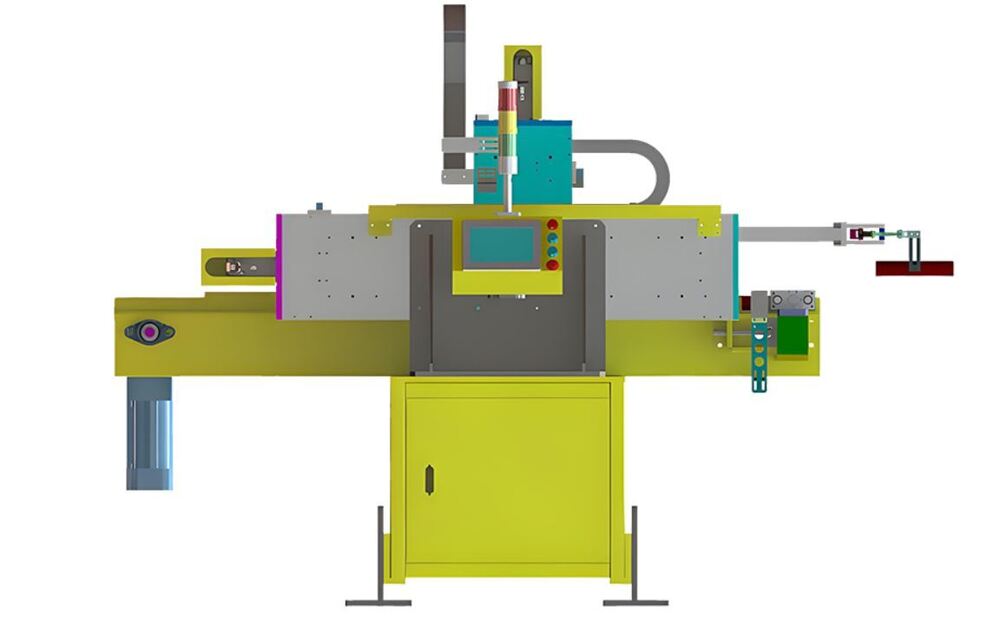

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A

Price 1500000 INR / Number

Minimum Order Quantity : 1 Number

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE S

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

TWO AXIS COORDINATE FORGING MANIPULATOR

Price 1600000 INR / Number

Minimum Order Quantity : 1 Number

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE H

Price 950000 INR / Number

Minimum Order Quantity : 1 Number

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry