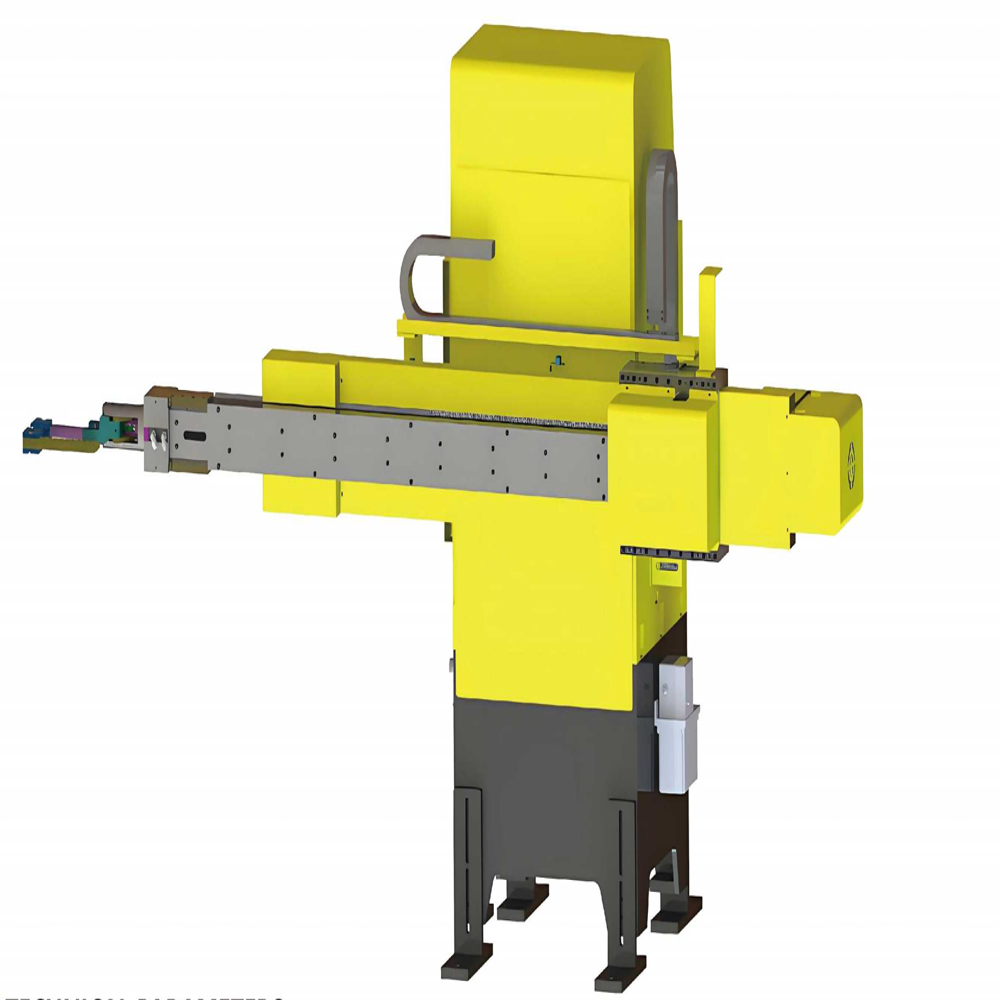

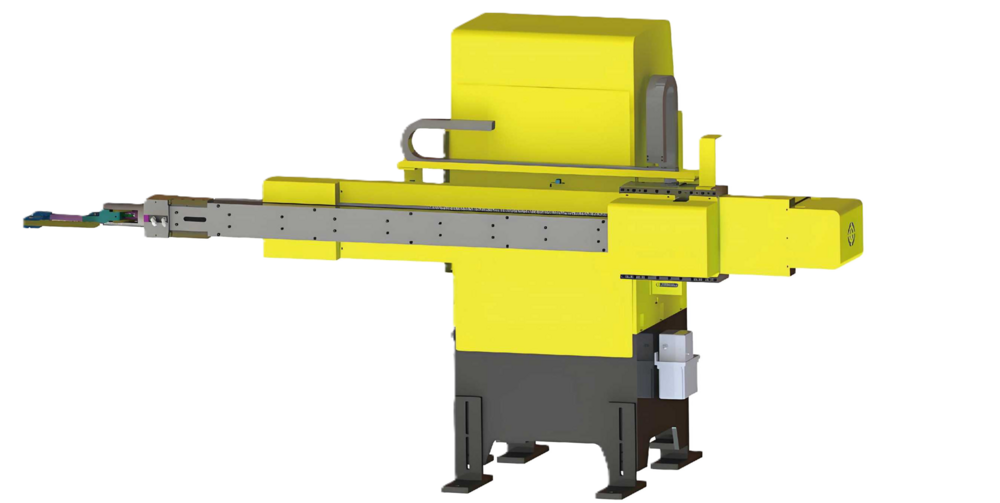

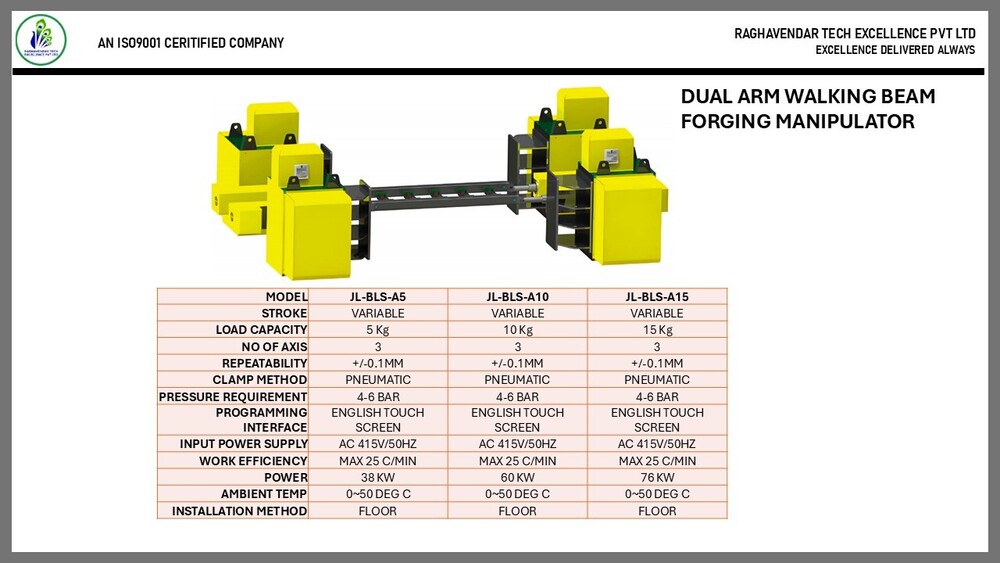

DUAL ARM WALKING BEAM FORGING MANIPULATOR

Price 2500000 INR/ Set

About DUAL ARM WALKING BEAM FORGING MANIPULATOR

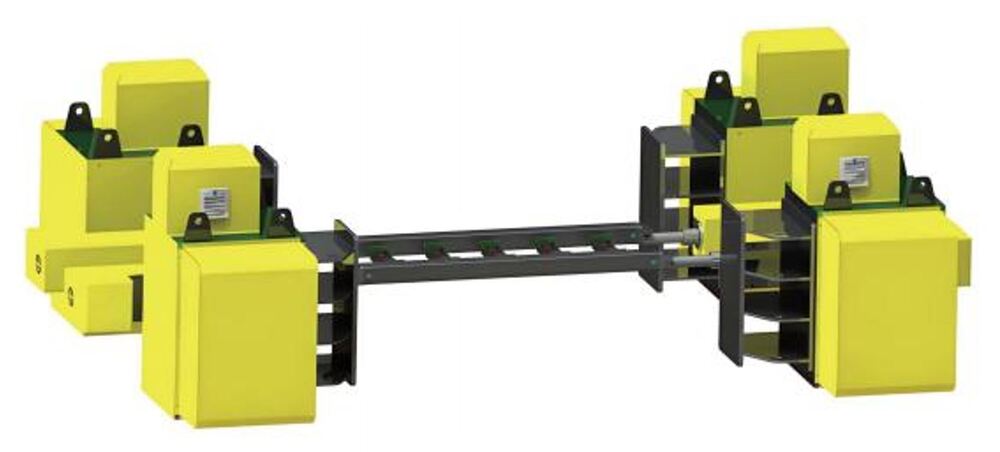

he V736 Dual-Arm Walking Beam Forging Manipulator is an advanced automation solution for forging operations. Integrated with 3 axes of coordinated motion and dual arms, this manipulator enables synchronized handling of workpieces, improving throughput while maintaining high precision.

Key Specifications:

-

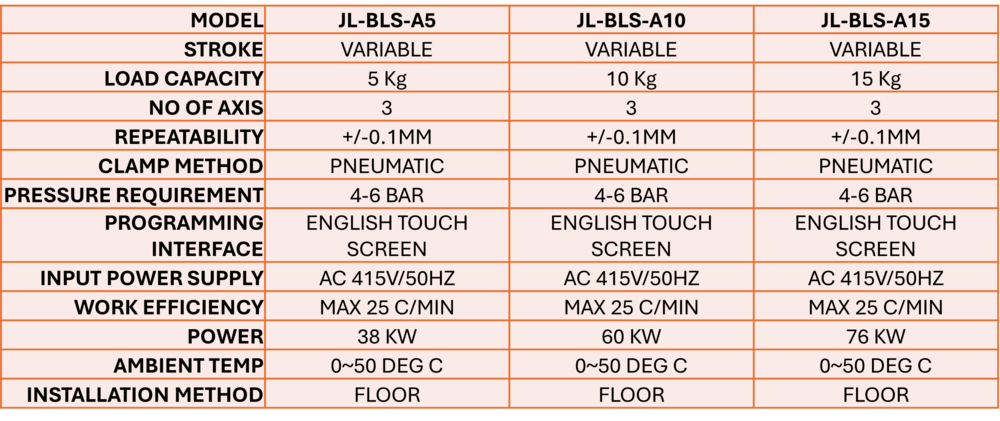

Model Variants: JL-BLS-A5 (5 kg), JL-BLS-A10 (10 kg), JL-BLS-A15 (15 kg)

-

Number of Axes: 3

-

Repeat Accuracy: +/- 0.1 mm

-

Clamping Method: Pneumatic

-

Air Pressure Requirement: 4.0 - 6.0 kg/cm2

-

Programming Interface: Bilingual touchscreen (Chinese & English)

-

Power Supply: AC 220V, 50/60 Hz

-

Work Efficiency: Up to 25 cycles per minute

-

Power Consumption:

-

-

A5: 38 kW

-

A10: 54 kW

-

A15: 70 kW

-

-

Ambient Operating Temperature: 0 C to 50 C

-

Installation Method: Body-mounted setup

Benefits & Applications:

-

Dual arms allow for simultaneous and balanced handling of forged parts, increasing cycle speed and stability.

-

Precise motion control (+/- 0.1 mm) helps ensure repeatable part positioning, improving quality.

-

Pneumatic clamp mechanism is fast and reliable, reducing clamp/unclamp times.

-

Suitable for moderate-weight forged components - from 5 kg to 15 kg, depending on model.

-

Designed for industrial forging lines, particularly where high throughput and automation are needed.

-

Helps improve safety by minimizing manual handling of hot, heavy parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FORGING MANIPULATOR Category

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A

Price 1500000 INR / Number

Minimum Order Quantity : 1 Number

TWO AXIS COORDINATE FORGING MANIPULATOR

Price 1600000 INR / Number

Minimum Order Quantity : 1 Number

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry