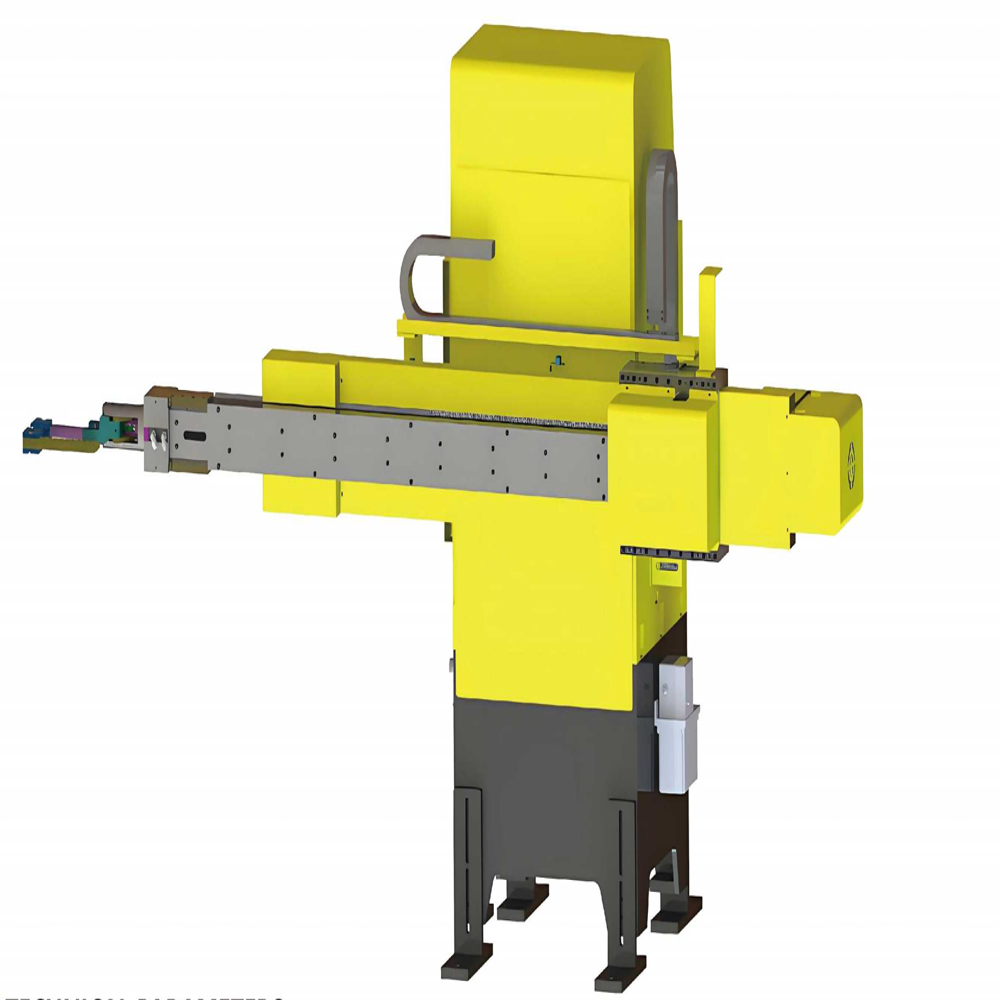

THREE AXIS SWING ARM FORGING MANIPULATOR

Price 1000000 INR/ Piece

About THREE AXIS SWING ARM FORGING MANIPULATOR

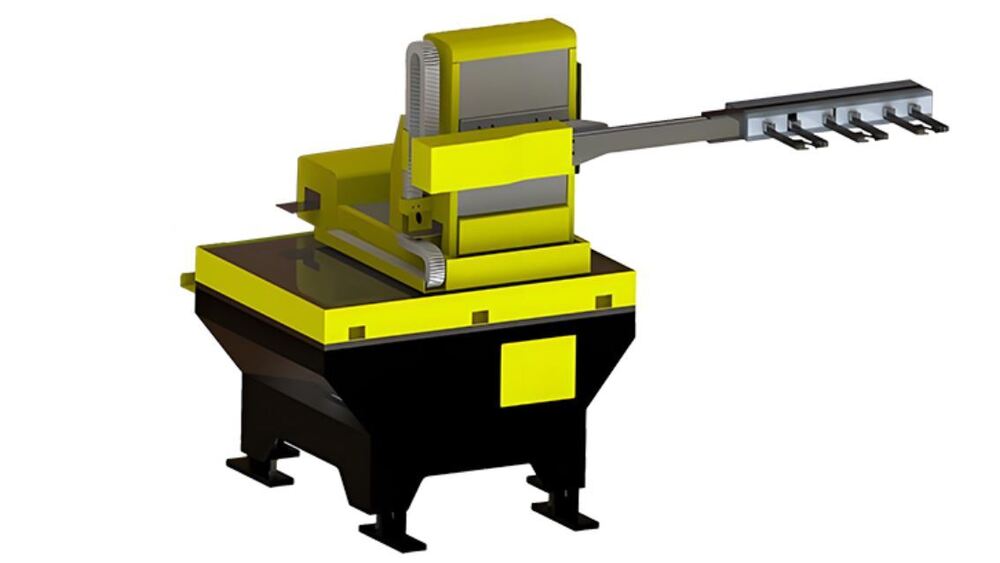

The Three-Axis Swing Arm Forging Manipulator is designed for precise, automated fabrication in forging lines. Featuring three-axis coordinated motion, it uses a swing-arm structure that enables agile and flexible handling of small forged components. The manipulator ensures consistent positioning with a repeat accuracy of +/- 0.2 mm, minimizing handling errors.

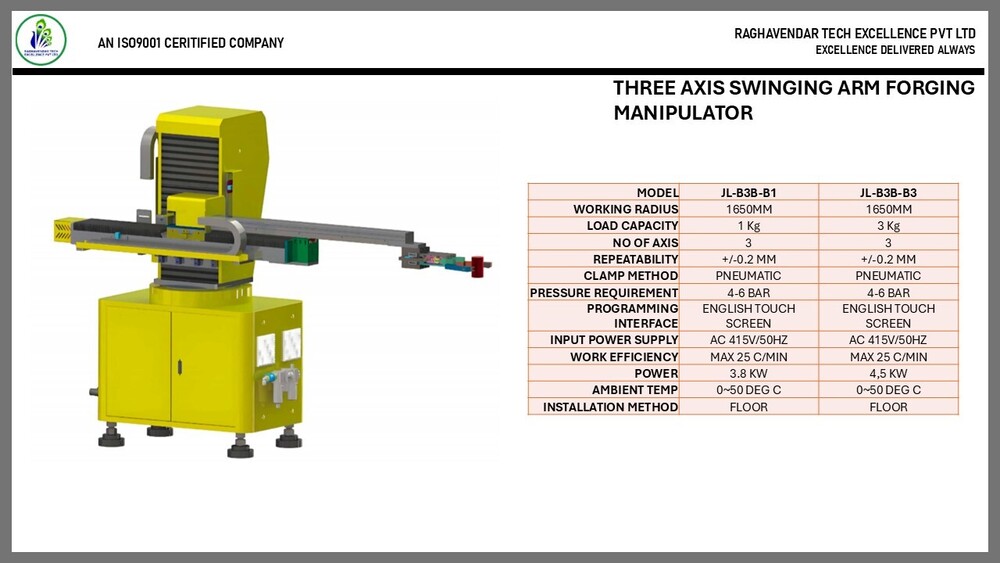

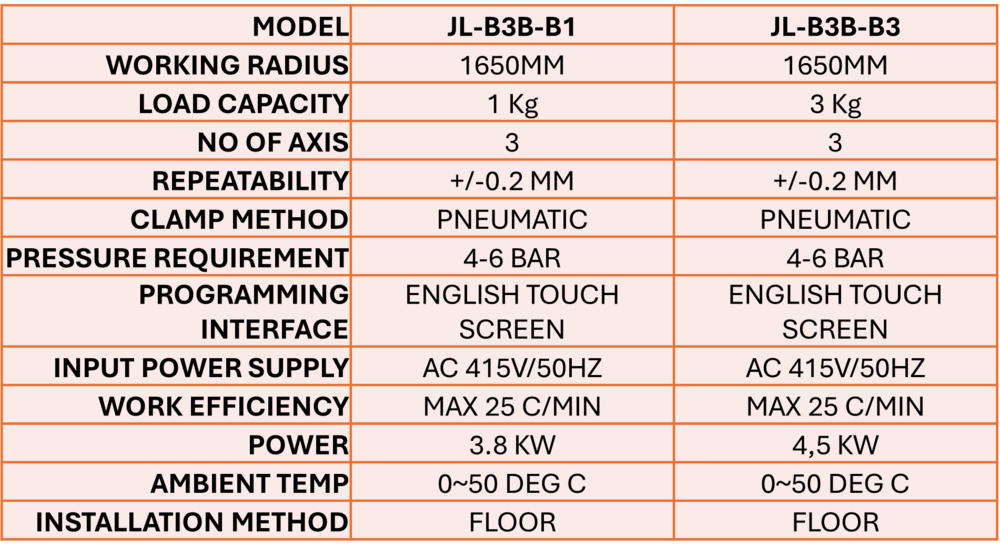

Key Technical Specifications:

-

Model Variants:

-

JL-B3B-B1: supports products up to 1 kg load.

-

JL-B3B-B3: supports products up to 3 kg load.

-

-

Axes: 3-axis movement for enhanced flexibility.

-

Repeat Accuracy: +/- 0.2 mm.

-

Clamp Method: Pneumatic gripping mechanism for fast and secure hold.

-

Air Pressure Requirement: 4.0 to 6.0 kg/cm2.

-

Programming Interface: Touch-screen control in Chinese and English.

-

Power Supply: AC 220 V, 50/60 Hz.

-

Work Efficiency: Up to approximately 25 cycles per minute.

-

Power Consumption:

-

JL-B3B-B1: 3.8 kW

-

JL-B3B-B3: 4.5 kW

-

-

Ambient Operating Temperature: 0 C to 50 C.

-

Installation Method: Floor-mounted for reliable operation.

Benefits & Applications:

-

The swing-arm design enables agile manipulation and efficient reach, suitable for tight or complex forging setups.

-

High repeat accuracy improves process consistency and reduces part rejection.

-

Pneumatic clamping ensures fast grip/release, boosting cycle times.

-

With two load variants (1 kg and 3 kg), it's well-suited for small to medium-sized forged parts.

-

Ideal for forging lines that require automated, precise, and repeatable handling, improving both safety and productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

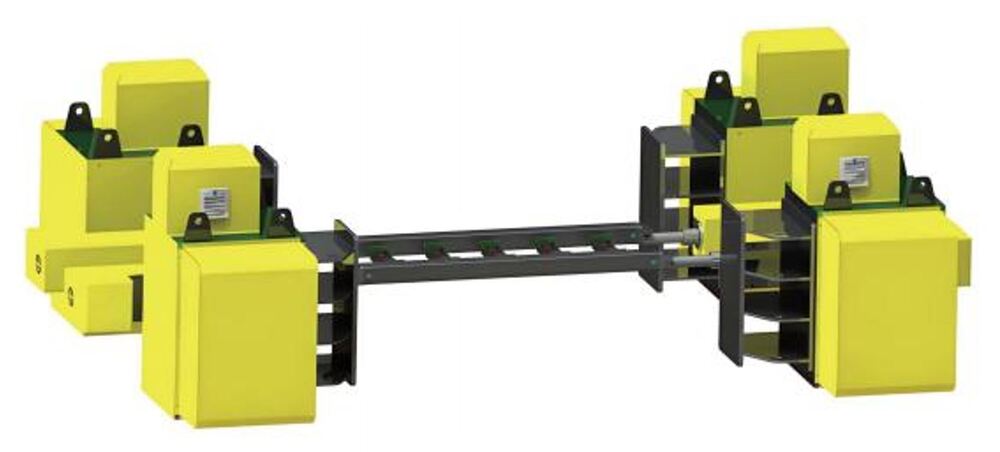

More Products in FORGING MANIPULATOR Category

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE A

Price 1500000 INR / Number

Minimum Order Quantity : 1 Number

THREE AXIS COORDINATE FORGING MANIPULATOR-TYPE S

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry