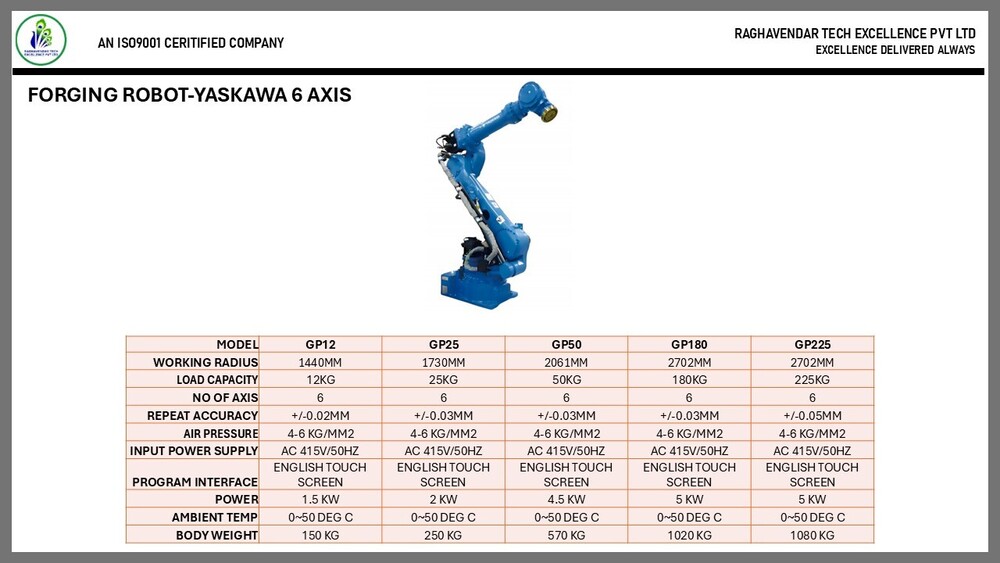

FORGING ROBOT-YASKAWA 6 AXIS

Price 1500000 INR/ Set

About FORGING ROBOT-YASKAWA 6 AXIS

The Yaskawa Six-Joint Forging Robot is a powerful and precise automation solution for forging lines. Leveraging six degrees of freedom, this robot offers excellent flexibility to manipulate workpieces with high repeatability, even under challenging industrial conditions.

Key Technical Specifications

-

Working Radius & Load Options: Based on Yaskawa GP series - for example, GP 12 model has working radius 1440 mm and 12 kg load capacity.

-

Number of Axes: 6 (full six-axis configuration).

-

Repeat Accuracy: +/- 0.02 mm.

-

Pneumatic Requirements: 4.0-6.0 kg/cm2

-

Programming Interface: Touchscreen, supports Chinese & English.

-

Power Supply / Control System: Standard industrial power (AC 380 V).

-

Ambient Operating Temperature: 0 C to 50 C (typical for these robots)

-

High Precision: Extremely tight tolerance handling thanks to its +/- 0.02 mm repeatability.

-

Flexibility & Reach: Six-axis design enables complex motions - especially useful for pick-and-place, orientation change, and multi-point tooling.

-

Improved Productivity: Automates repetitive tasks in forging lines, reducing manual labor and increasing throughput.

-

Durable & Reliable: Pneumatic system combined with robust mechanics ensures long operational life even under harsh forging environments.

-

User-Friendly Operation: Touchscreen control in two languages makes programming and maintenance easier.

-

Wide Application: Suitable for die forging, free forging, crankshafts, and other high-precision forged components.

- Ideal for plants upgrading to automated forging lines.

-

Perfect for applications requiring both load capacity and fine positional accuracy.

-

Designed to integrate with existing Yaskawa-compatible systems or as a standalone robotic cell.

Benefits & Applications

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry