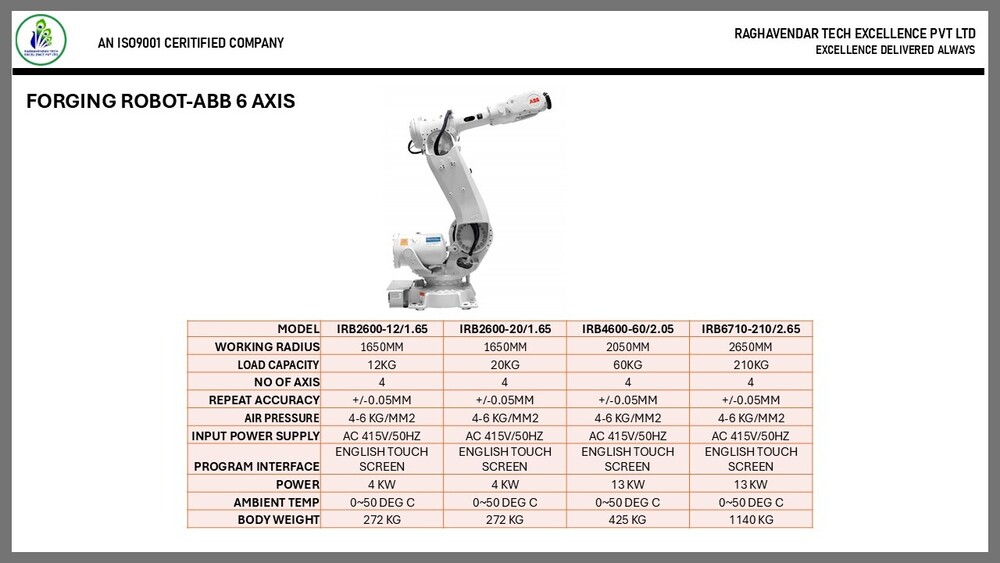

FORGING ROBOT-ABB 6 AXIS

Price 2000000 INR/ Set

About FORGING ROBOT-ABB 6 AXIS

The ABB Six-Joint Forging Robot is a reliable and precise automation solution for forging lines, especially suited for medium-duty forging tasks. Built on ABB's proven 6-axis architecture, this robot provides excellent motion flexibility, high repeatability, and consistent performance under industrial conditions.

Key Technical Specifications

-

Working Radius: Approximately 1,650 mm to 2600 mm.

-

Payload / Load: 20 to 200 kg.

-

Number of Axes: 6-axis design enables full spatial movement and complex manipulations.

-

Repeat Accuracy: +/- 0.04 mm for tight precision.

-

Pneumatic Requirements: Operates on air pressure between 4.0 and 6.0 kg/cm2.

-

Programming Interface: Touchscreen interface supporting both Chinese and English for ease of use.

-

Power Supply: AC 380V, 50/60 Hz (standard industrial power).

-

Operating Ambient Temperature: Designed for a temperature range of 0 C to 50 C, making it suitable for typical forging workshop environments.

-

Installation Method: Floor-mounted for robust and stable integration in the production setup

-

High Accuracy Handling: +/- 0.04 mm repeatability ensures precise placement and manipulation, which is critical for forged parts.

-

Versatile Motion: 6-axis architecture allows for complex trajectories, making it ideal for multi-step forging processes.

-

Reduced Manual Labor: Automates repetitive tasks, minimizing manual intervention, increasing productivity, and improving safety.

-

Durable & Reliable: Built to handle the tough conditions of forging environments with a sturdy frame and proven ABB robotics technology.

-

User-friendly Programming: Touchscreen interface simplifies setup, programming, and maintenance even for operators with lesser experience.

-

Ideal For: Medium-load forging operations - such as die forging, forging of smaller to medium components, and automated handling tasks where precision and repeatability are needed.

Benefits & Applications:

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry