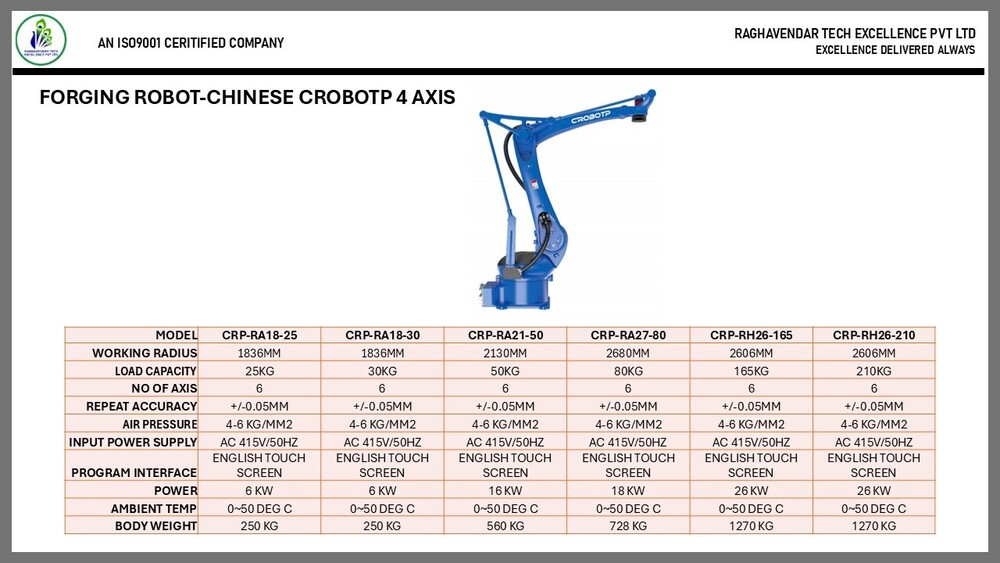

FORGING ROBOT-CHINESE CROBOTP 4 AXIS

Price 1000000 INR/ Set

About FORGING ROBOT-CHINESE CROBOTP 4 AXIS

The Four-Joint Forging Robot is a compact and high-precision automation solution tailored for forging applications. With four axes of motion and a lightweight design, this robot can accurately manipulate parts with a payload of 15 kg.

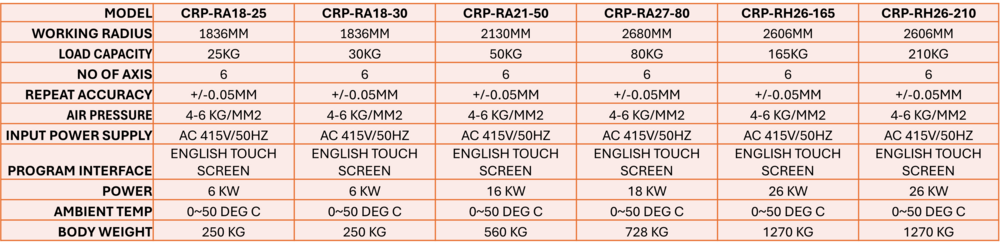

Key Specifications:

-

Working Radius: 1,530 3130 mm

-

Payload / Load Capacity: 15 - 180kg

-

Number of Axes: 4 (four-axis robot)

-

Repeat Accuracy: 0.08 to 0.2mm, ensuring very precise and repeatable motion

-

Air Pressure Requirement: 4.0 - 6.0 kg/cm2 (pneumatic drive)

-

Programming Interface: Touchscreen, supports both Chinese and English for easy operation

-

Input Power Supply: AC 220 V, 50 / 60 Hz

-

Power Consumption: 4 kW for the 15 kg version

-

Ambient Operating Temperature: 0 C to 50 C

Benefits & Applications:

-

Enhances productivity by automating repetitive forging tasks with high precision.

-

Reduces manual labor and improves workplace safety.

-

Ideal for handling medium-weight components in forging, where both reach and accuracy are important.

-

Flexible programming interface makes setup and operation user-friendly.

-

Suitable for continuous production environments due to its stable and reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry