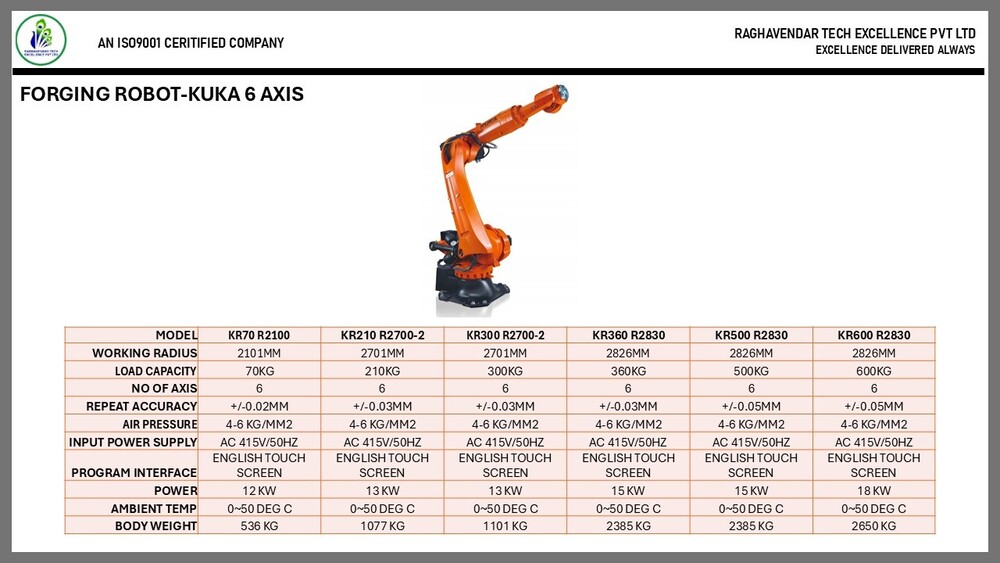

FORGING ROBOT-KUKA 6 AXIS

Price 2100000 INR/ Set

About FORGING ROBOT-KUKA 6 AXIS

The V729 KUKA Six-Joint Forging Robot is a powerful automation solution tailored for heavy-duty forging operations. With six degrees of freedom, it can handle large and complex forged parts with high precision and flexibility. This robot is ideal for forging lines where both reach and load capacity are critical.

Key Technical Specifications

-

Working Radius: Approximately 2,101 mm for lighter payload model; up to 2,826 mm for higher-capacity variants.

-

Payload Variants: 70 kg, 210 kg, 300 kg, 360 kg, 500 kg, 600 kg.

-

Number of Axes: 6-axis configuration, enabling complex spatial motions and precise part handling.

-

Repeat Accuracy: +/- 0.05 mm for lighter models; +/- 0.08 mm for heavier variants.

-

Pneumatic Pressure Requirement: 4.0-6.0 kg/cm2.

-

Programming Interface: Touchscreen control with support for both Chinese and English languages.

-

Power & Control System: Standard industrial control architecture (with pneumatic actuation).

-

Operating Environment: Designed for workshop conditions common in forging plants.

-

High Precision: Tight repeatability ensures consistent handling, reducing defects and improving quality.

-

Flexible Motion: The six-axis design offers full spatial flexibility - ideal for pick-and-place, orientation changes, and complex manipulations.

-

Efficiency Gains: Automation of large, repetitive tasks reduces manual labor and increases cycle throughput.

-

User-friendly Operation: A bilingual touchscreen interface simplifies programming, reduces training needs, and speeds up commissioning.

-

Robust Design: Built to withstand harsh forging environments and long production hours.

Ideal For -

Large forging plants working with high-weight components.

-

Die forging, ring rolling, crankshaft/manifold forging, and other high-precision, high-volume part production.

-

Automating tasks where both strength and accuracy are required especially for heavy or awkwardly shaped forged items

Heavy-duty Capacity: With very high payload options (up to 600 kg), this robot can manage large forged billets and heavy dies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry