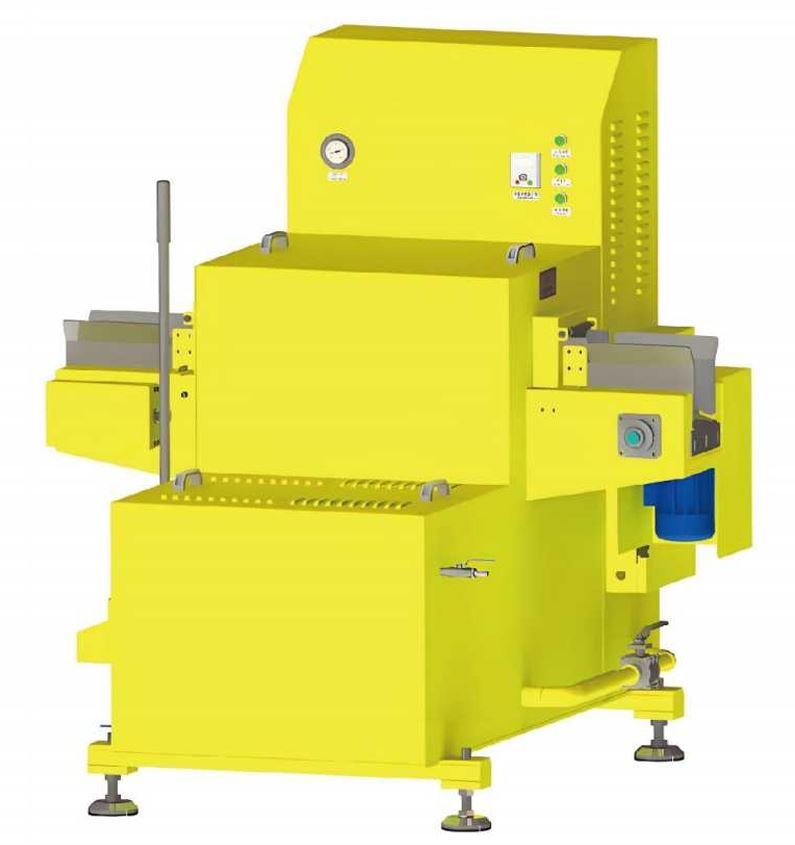

FORGING DESCALER

Price 1200000 INR/ Set

About FORGING DESCALER

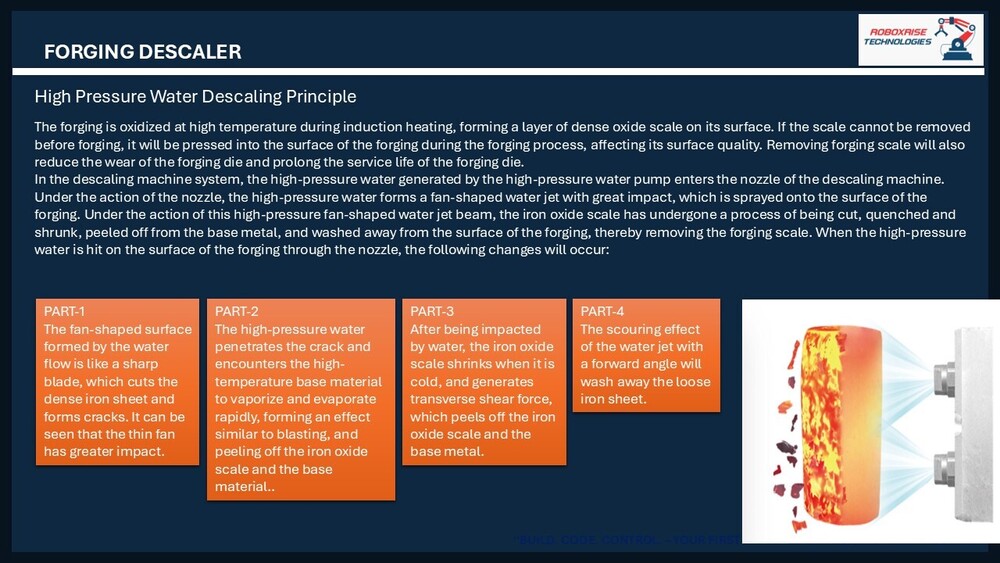

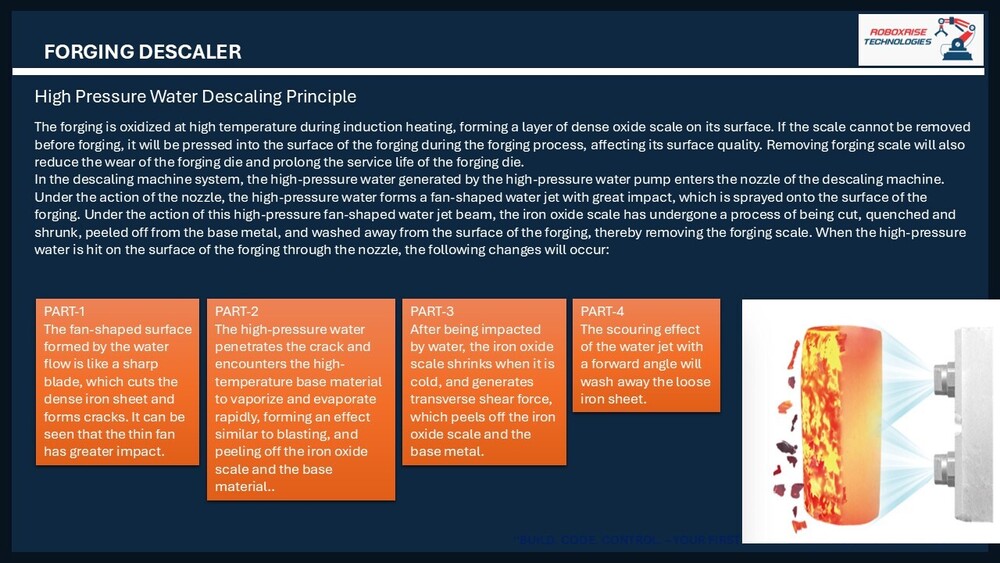

The forging is oxidized at hightemperature during induction heating, forming a layer of dense oxide scale onits surface. If the scale cannot be removed before forging, it will be pressedinto the surface of the forging during the forging process, affecting itssurface quality. Removing forging scale will also reduce the wear of theforging die and prolong the service life of the forging die.

In the descaling machine system, thehigh-pressure water generated by the high-pressure water pump enters the nozzleof the descaling machine. Under the action of the nozzle, the high-pressurewater forms a fan-shaped water jet with great impact, which is sprayed onto thesurface of the forging. Under the action of this high-pressure fan-shaped waterjet beam, the iron oxide scale has undergone a process of being cut, quenchedand shrunk, peeled off from the base metal, and washed away from the surface ofthe forging, thereby removing the forging scale. When the high-pressure wateris hit on the surface of the forging through the nozzle, the following changeswill occur:

PART-1

The fan-shaped surface formed by thewater flow is like a sharp blade, which cuts the dense iron sheet and formscracks. Itcan be seen that thethin fan has greater impact.

PART-2

The high-pressure water penetratesthe crack and encounters the high-temperature base material to vaporize andevaporate rapidly, forming an effect similar toblasting, and peeling off the iron oxide scale and the base material..

PART-3

After being impacted by water, theiron oxide scale shrinks when it is cold, and generates transverse shear force,which peels off the iron oxide scale and the base metal.

PART-4

The scouring effect of the waterjet with a forward angle will wash away the loose iron sheet.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry